How Laser Galvo Systems Enhance the Efficiency of 3D Printing and Imaging

How Laser Galvo Systems Enhance the Efficiency of 3D Printing and Imaging

Blog Article

Recognizing Why You Need Galvo for Accuracy in Laser Applications

The assimilation of galvo innovation in laser applications represents a considerable improvement in accomplishing precision and effectiveness. By using high-speed mirrors to guide the laser light beam, galvo systems not just boost functional rate but likewise preserve the precision needed for complicated tasks such as inscription and cutting.

What Is Galvo Technology?

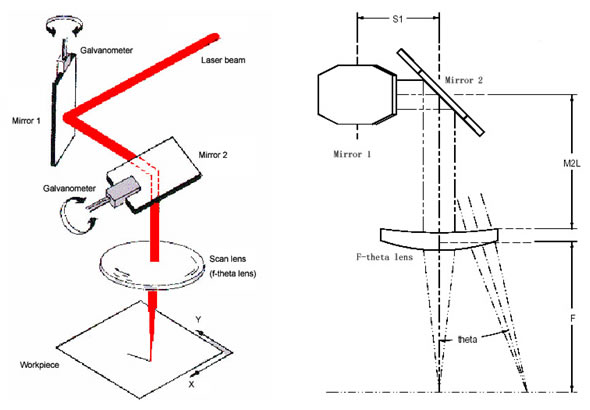

Galvo modern technology, brief for galvanometer technology, is an accuracy control system that uses mirrors installed on galvanometer electric motors to direct laser light beams with high precision. This innovative method allows for specific and quick positioning of laser light, making it an important part in different laser applications, consisting of engraving, reducing, and noting.

In a normal galvo system, the galvanometer electric motors are in charge of turning the mirrors. The electronic control system equates the desired laser course right into electrical signals, which advise the motors to relocate the mirrors as necessary. This enables the laser light beam to be routed at certain angles and locations with very little latency, enhancing the efficiency of the laser process.

Galvo modern technology is particularly advantageous in applications that need high-speed operation and complex styles, as it lowers the mechanical motion of the laser resource. Instead, the mirrors can promptly rearrange the beam of light, allowing intricate patterns and layouts to be carried out with accuracy. The ability to rapidly alter the direction of the laser beam of light while preserving precision is what establishes galvo innovation apart, making it a foundation of modern-day laser machinery and applications.

Advantages of Galvo Equipments

Among the essential advantages of employing galvo systems in laser applications depends on their capacity to enhance operational rate and performance. Unlike standard laser systems that rely upon moving the whole laser head, galvo systems make use of high-speed mirrors to route the laser beam. This substantially decreases the time required for placing and permits rapid handling of facility patterns.

One more advantage is their small layout, which facilitates combination right into various arrangements without calling for extensive modifications. This space-saving characteristic enables higher versatility in laser system layout, fitting varied operational atmospheres.

Moreover, galvo systems can manage a large range of materials and densities, making them versatile tools in laser handling. Overall, the advantages of galvo systems-- boosted speed, convenience, density, and precision-- make them an important option for modern laser applications.

Applications in Laser Processes

Numerous applications in laser processes benefit from the precision and speed provided by galvo systems. These systems are important to sectors such as engraving, cutting, and noting, where precision and speed directly impact productivity and product quality. In laser inscription, galvo mirrors allow specific and quick activity across complex surface areas, permitting for detailed layouts to be etched onto numerous products without jeopardizing detail.

Additionally, in the medical area, galvo-driven lasers are used in procedures like laser surgical procedure and cells ablation, where pinpoint precision is crucial for client safety and security and reliable therapy. Galvo Scanner. Overall, the flexibility and responsiveness of galvo systems make them crucial in various laser applications, driving technology and enhancing functional capacities across numerous fields

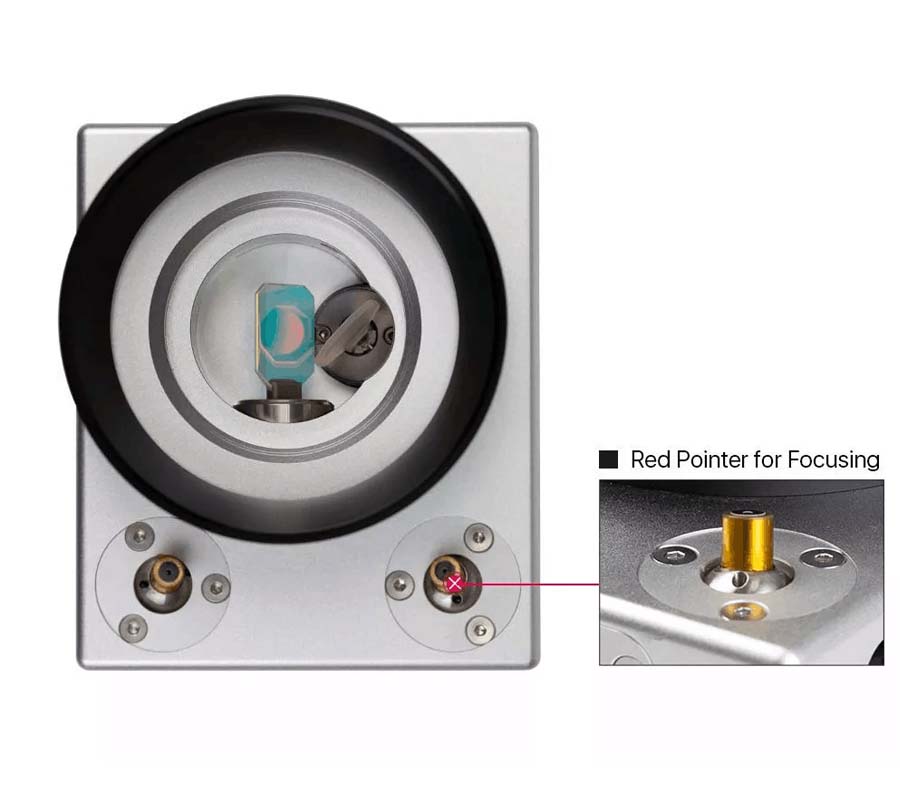

Trick Attributes of Galvo Mirrors

A vital element in laser systems, galvo mirrors are made to provide fast and specific beam steering, enabling high-performance applications. One of the essential features of galvo mirrors is their speed; they can attain quick angular activities, permitting fast feedback times vital in applications such as laser inscription, cutting, and scanning.

One more significant function is their high precision and accuracy. Galvo mirrors can position the laser light beam with marginal inconsistency, which is important for jobs that need specific placement and repeatability. This precision is promoted by advanced control systems that can compensate for any kind of potential mistakes in real-time.

In addition, the portable style of galvo mirrors enables for assimilation into smaller systems without endangering efficiency. Their lightweight construction also adds to reduced inertia, additional boosting their responsiveness during operation.

Moreover, the resilience and dependability of galvo mirrors make them appropriate for constant usage sought after atmospheres. This resilience guarantees constant efficiency with time, lessening downtime due to maintenance or repair work. Generally, the distinct features of galvo mirrors make them vital for accomplishing high precision and efficiency in different laser applications.

Selecting the Right Galvo System

Choosing an appropriate galvo system is critical for maximizing laser efficiency across various applications. When selecting a galvo system, a number of elements must be thought about to make certain compatibility with certain task needs. Analyze the needed scanning rate and resolution, as these parameters determine the galvo's motor requirements and mirror size. A greater resolution may necessitate advanced galvo systems with faster reaction times.

One more essential factor is the type of laser being made use of. Various lasers, such as CO2 or fiber lasers, have distinct needs pertaining to wavelength and power, affecting the option of galvo mirrors. Guarantee that the selected system is developed to manage look at here the particular wavelength and power of your laser for ideal performance.

Furthermore, think about the software application compatibility and control options offered with the galvo system. A well-integrated software program solution can improve functional effectiveness and make it possible for precise control over scanning patterns.

Last but not least, review the manufacturer's track record and support services. A trusted producer will supply not just premium products yet additionally ongoing technical assistance, which is essential for keeping system efficiency. By very carefully thinking about these aspects, you can choose a galvo system that fulfills your specific laser application needs.

Verdict

In recap, galvo modern technology plays a pivotal duty in boosting accuracy and performance in laser applications. The benefits of high-speed mirror systems promote precise and fast laser light beam instructions, making them special info essential for detailed jobs such as engraving, reducing, and marking. By decreasing mechanical activity, galvo systems ensure cleaner sides and in-depth layouts, thereby satisfying the demanding requirements of numerous industries. Selecting the appropriate galvo system is critical for maximizing performance in laser processes.

The capability to quickly alter the direction of the laser beam while maintaining accuracy is what establishes galvo technology apart, making it a cornerstone of contemporary laser equipment and applications.

Unlike conventional laser systems that count on relocating the whole laser head, galvo systems make use of high-speed mirrors to direct the laser beam of light.Various applications in laser processes benefit from the precision and speed provided by galvo systems (Laser Galvo).In laser cutting applications, galvo systems improve the capacity to procedure materials such as metal, timber, and plastics with high precision, making certain tidy edges and marginal kerf width. Different lasers, such as CO2 or fiber lasers, have distinct needs regarding wavelength and power, influencing the option of galvo mirrors

Report this page